Technology

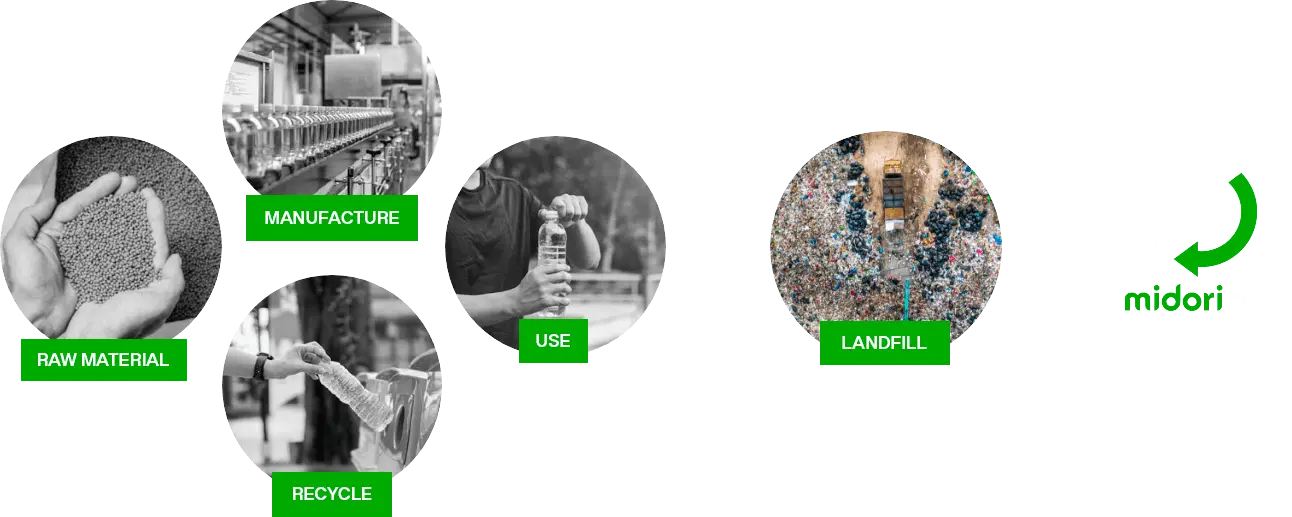

Midori Biorecyclable Solutions

Accelerating the natural biorecycling process

The Midori Biosolutions additive can be applied to nearly all polymer types, processes, and applications to reduce the amount of waste taking up space in landfills.

How it works

Integrating our technology into plastics speeds the biorecycling process to just a few years*, vs 300 to 1000 years.

Step 1

Integrate additive during extrusion or compounding stage

Step 2

Opens polymer chain allowing water & microbes to enter

Step 3

Breaks down to “Element” level:

- Inert humus, which makes soil richer

- Biogas, promotes renewable energy development

Key benefits

A sustainable solution for plastics, textiles and other synthetics

- Biorecycling only starts when in active landfill or marine environment

- Plastic breaks down at a molecular level harnessing natures microbes

- 100% organic and non-starch based, no heavy metals, non-toxic.

- Leaves behind no microplastics/nanoplastics at end of life

- 5-15% biorecycling in the first 30 days

- Provides mechanism to convert plastic into potential renewable gas

Integration

We offer a cost-effective end-of-life solution for all plastics

Whether a plastic is flexible or rigid, and is extruded, molded, thermoformed, spun, compounded, or laminated, our cost-effective additive can make it biorecyclable in a biologically active landfill.

Applications

Integrates seamlessly into most manufacturing processes

Products made with our easy-to-use technology have the same physical properties and tensile strength. This means the plastics will perform just as well as those manufactured without our technology, but with the added benefit of biorecycling when discarded in a biologically active landfill.

- Poly bags; retail, wholesale

- All types of footwear

- Retail sporting goods products and packaging

- Fibre filaments, textiles, capeting

- Food and foodservice package

- Water bottles BOPP film, PET film

- Front End Grocery Shopping bags, Trash Bags, Nylon Straps

- Medical surgical drapes, patient table covers, disposable bags, medical PPE and nitrile gloves

- Protective packaging bubble wrap and foam, packing envelopes

Certifications

Food Contact Safe and FDA Compliant

Our technology is 100% organic, non-toxic, and non-starch based. It leaves behind no microplastics or nanoplastics and creates a renewable energy source that can qualify for a carbon offset.

- Food Contact Compliant – FDA (USA), ANVISA (Brazil), FAST (Europe)

- Compliant with US CONEG (Coalition of Northeastern Governors)

- Compliant to CA Prop 65 (California Safe Drinking Water Act)

- Free of BPA, phthalates, and toxic materials such as lead, cadmium, hexavalent chromium and mercury

- Zero heavy metals

- Terrestrial Plant Toxicity Test (Certified ASTM E1963)

Contact Us

For more information on our trusted CPG customers please contact us

Our Mission

The planet is in need of sustainable solutions

Textile Solutions

Create high-performance textiles without the carbon footprint

*Based on ASTM D5511 testing result rates.